The Unique Geometry of Delta Printing

Delta 3D printers represent a radical departure from traditional Cartesian printing systems. Unlike rectangular printers with fixed X and Y axes, delta printers utilize a revolutionary triangular design that fundamentally reimagines 3D printing kinematics.

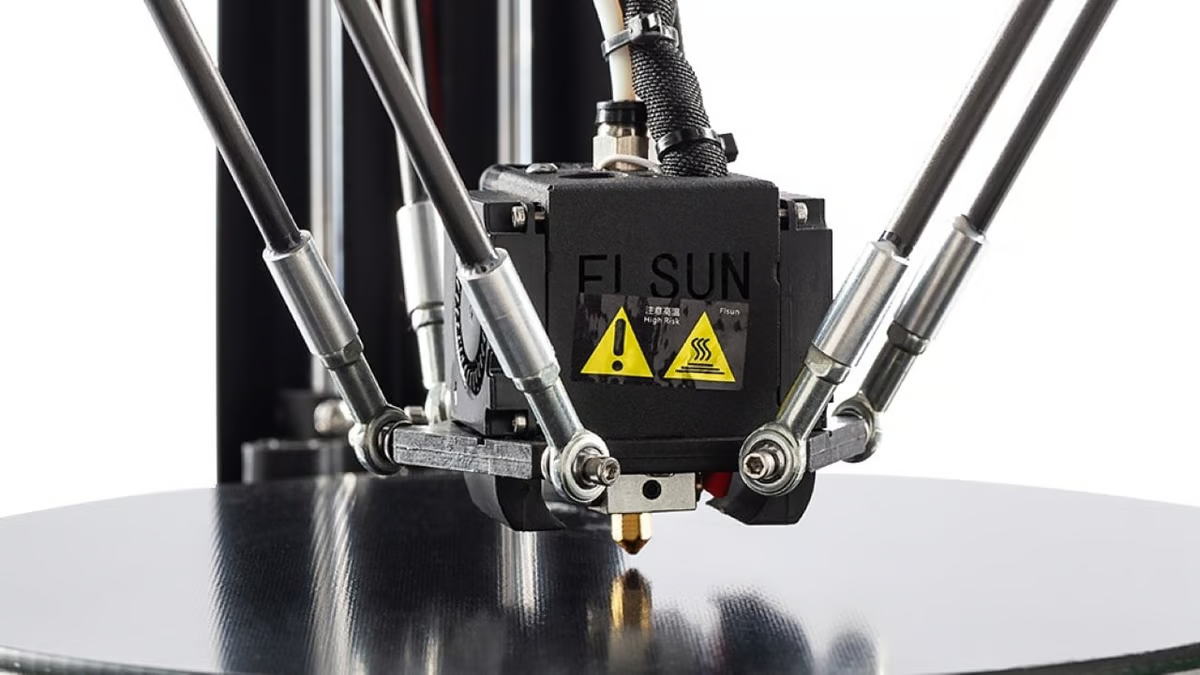

Structural Anatomy of Delta Printers

- Three vertically mounted parallel arms

- Central suspended print head

- Triangular frame configuration

- Unique parallel kinematic system

- Simplified mechanical design

Historical Development

The delta printer concept emerged from innovative thinking about printer motion systems. Developed as an alternative to traditional rectangular 3D printer designs, delta printers were initially conceived to address specific manufacturing limitations.

Key Evolutionary Milestones:

- First conceptualized in early 2010s

- Originated from industrial robotic arm designs

- Rapidly adopted by open-source 3D printing community

- Continuous refinement through collaborative development

Mechanical Advantages

Delta printers offer several unique mechanical benefits:

Speed and Acceleration

- Lightweight print head

- Reduced moving mass

- Extremely rapid directional changes

- Higher potential acceleration rates

- Smoother motion trajectories

Vertical Build Volume Optimization

- Tall, cylindrical print volumes

- Excellent height-to-footprint ratio

- Minimal horizontal space requirements

- Ideal for tall, slender prints

Kinematic Principles

The delta printer’s core innovation lies in its parallel arm system:

- Each arm moves independently

- Synchronized through complex mathematical calculations

- Trigonometric positioning algorithms

- Precise coordinated movements

Computational Complexity

- Requires advanced firmware

- Complex inverse kinematics calculations

- Real-time positional adjustments

- Sophisticated motion planning

Design Variations

Delta printers have evolved into multiple design categories:

Classic Delta Configurations

- Three-arm symmetrical design

- Traditional parallel arm configuration

- Most common consumer configuration

Advanced Configurations

- Linear delta variations

- Modified arm lengths

- Adjustable arm geometries

- Experimental motion systems

Printing Performance Characteristics

Strengths

- Exceptional vertical print capabilities

- Rapid print speeds

- Minimal vibration

- Lightweight design

- Excellent for tall, cylindrical objects

Limitations

- Challenging first layer calibration

- Less precise for very large flat surfaces

- Complex initial setup

- Steeper learning curve

Calibration and Maintenance

Delta printers require specialized calibration techniques:

- Precise arm length measurements

- Complex geometric alignment

- Advanced firmware configuration

- Regular geometric verification

Calibration Challenges

- Requires mathematical precision

- Multiple adjustment points

- Time-consuming initial setup

- Specialized knowledge required

Materials and Compatibility

Most delta printers support:

- Standard FDM filaments

- PLA

- PETG

- ABS

- Specialized exotic filaments

- Some high-temperature materials

Notable Delta Printer Models

Community Favorites

- Rostock MAX

- SeeMeCNC Orion

- FLSUN QQS Pro

- Delta WASP

- RepRap Morgan

Emerging Technologies

Future delta printer developments include:

- Improved calibration algorithms

- Advanced motion control systems

- Integration of machine learning

- Enhanced thermal management

- More sophisticated firmware

Industry and Research Applications

Delta printers find unique applications in:

- Architectural modeling

- Rapid prototyping

- Educational demonstrations

- Specialized vertical manufacturing

- Research prototype development

Economic and Market Perspective

Market Trends

- Growing niche market segment

- Increasing professional adoption

- Continued technological refinement

- Expanding application diversity

Projected Market Growth

- Estimated 15-20% annual growth

- Increasing professional applications

- Continued technological innovation

Conclusion

Delta 3D printers represent a fascinating alternative to traditional printing geometries. Their unique design offers unprecedented capabilities in vertical printing, speed, and mechanical simplicity. As technology continues to evolve, delta printers will likely play an increasingly important role in advanced manufacturing and prototyping technologies.