The Biological Printing Frontier

Bioprinting represents the most revolutionary application of 3D printing technology in medical science. This cutting-edge technique involves creating living tissue structures layer by layer, using specialized bio-inks composed of living cells, growth factors, and supportive biomaterials.

Advanced Bioprinting Techniques

- Extrusion-based bioprinting

- Laser-assisted bioprinting

- Inkjet bioprinting

- Stereolithographic bioprinting

Current breakthrough areas include:

- Skin tissue reconstruction

- Bone and cartilage regeneration

- Functional organ prototype development

- Personalized tissue engineering

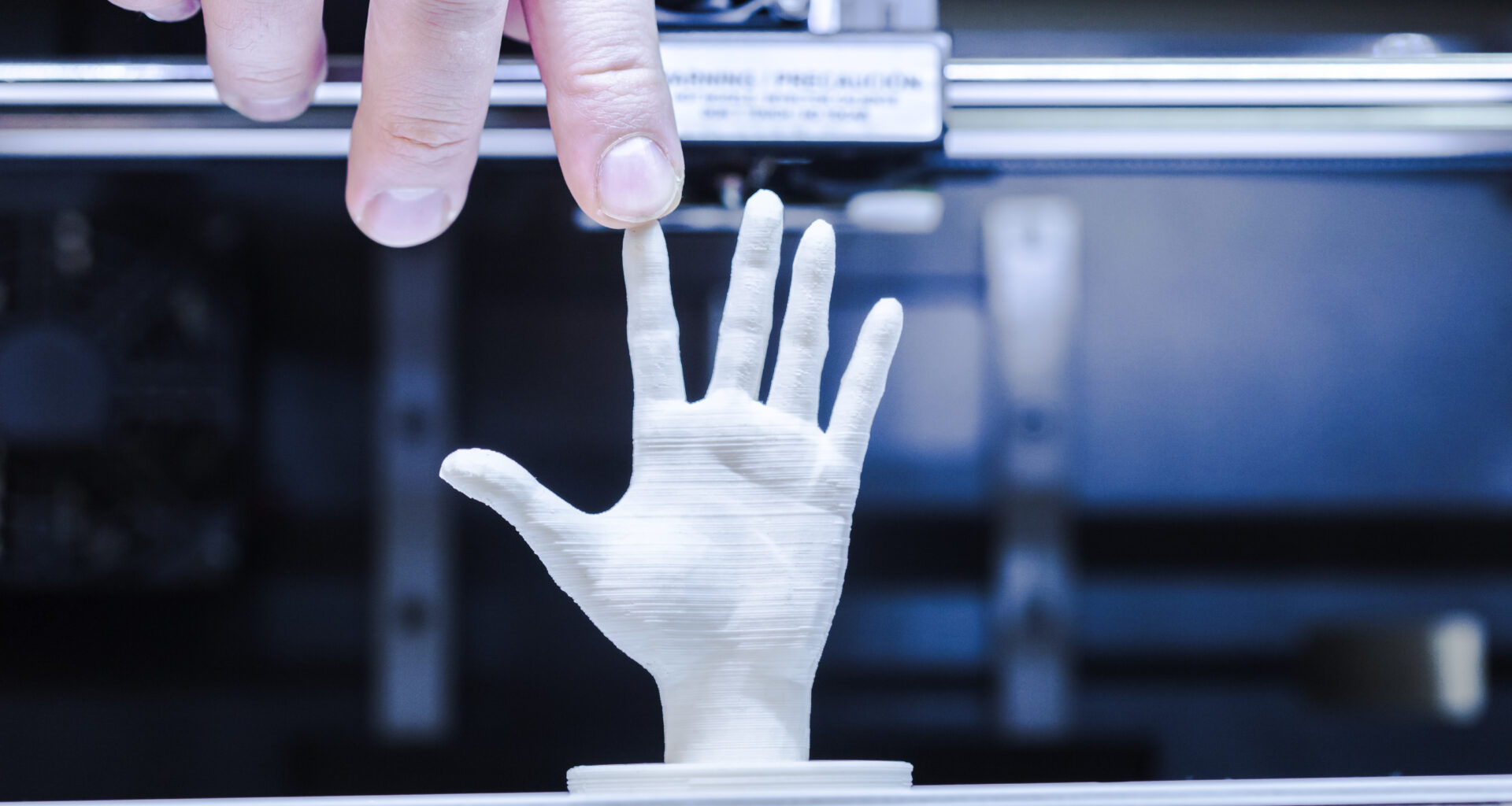

Prosthetic and Orthotic Innovations

3D printing has transformed prosthetic design, enabling:

- Fully customized limb replacements

- Rapid prototyping of adaptive devices

- Significantly reduced production costs

- Complex geometries impossible with traditional manufacturing

Child prosthetics benefit dramatically, with 3D printing allowing quick, affordable replacements as children grow. Custom-fit prosthetics can now be produced in days instead of weeks, dramatically improving patient outcomes.

Surgical Planning and Medical Education

Advanced 3D printed anatomical models provide unprecedented surgical preparation capabilities:

- Exact patient-specific organ replicas

- Surgical technique practice

- Complex procedure visualization

- Medical student training models

Surgeons can now:

- Rehearse complicated surgeries

- Understand unique patient anatomies

- Develop precise surgical approaches

- Reduce operational risks

Dental Applications

The dental industry has been revolutionized by 3D printing technologies:

- Custom dental implants

- Precise crown and bridge manufacturing

- Orthodontic alignment tools

- Rapid denture production

- Surgical guides for dental procedures

Digital scanning combined with 3D printing allows for millimeter-precise dental reconstructions, dramatically improving patient outcomes and reducing production times.

Pharmaceutical Applications

3D printing is transforming medication production:

- Personalized medication dosages

- Complex drug release mechanisms

- Patient-specific pill formulations

- Rapid pharmaceutical prototyping

Researchers are developing 3D printed pills with:

- Precise chemical compositions

- Customized release profiles

- Unique geometric designs for controlled absorption

Challenges and Future Perspectives

Current limitations include:

- High equipment costs

- Complex regulatory approvals

- Material limitations

- Scaling production challenges

Emerging research focuses on:

- More advanced biomaterials

- Improved printing resolution

- Enhanced cellular viability

- Faster printing technologies

Ethical and Regulatory Considerations

The medical 3D printing field faces significant ethical challenges:

- Patient data privacy

- Regulatory compliance

- Standardization of medical 3D printed products

- Long-term safety assessments

Economic Impact

The medical 3D printing market is projected to reach:

- $3.5 billion by 2025

- Compound annual growth rate of 17.5%

- Significant job creation in medical technology

Emerging Technologies

Cutting-edge research explores:

AI-assisted design optimization

4D bioprinting with time-responsive materials

Stem cell printing techniques

Nano-scale tissue engineering